DigitalFabrication_8950_liteBeam-C-01

DigitalFabrication_8950_liteBeam-B

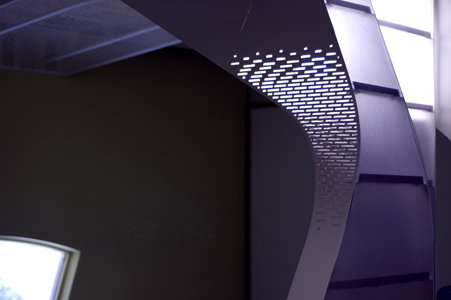

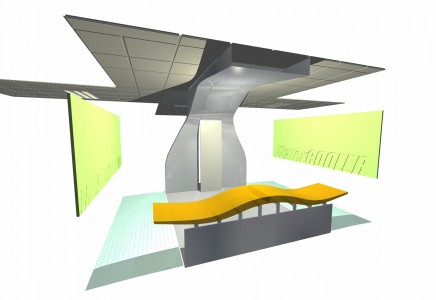

LITEBEAM Lite Beam was a function of available local fabrication resources, as well as a basic desire to modify and expand the parameters of the typical “suspended ceiling system”. Primary elements – beams – were conceived as sculpted solid forms, complex shapes that are simple catenary expressions of a uniform load over a simple span. Between each beam is a series of vertical lenses, CNC router-cut from ½” thick clear plexi-glass. These are embedded with colored cold-cathode lighting, and support a series of fluorescent single tube fixtures that provided indirect lighting between each of the 4 beams. Below the lenses and in between each beam are a series of three shells – concave space frames that serve to capture and diffuse the light emitted from the fluorescent tubes and the edges of the lenses. While this iteration of the LiteBEAM System extends for 4 modules, it is understood as a repetitive system that could extend indefinitely.

DigitalFabrication_8950_liteBeam-A

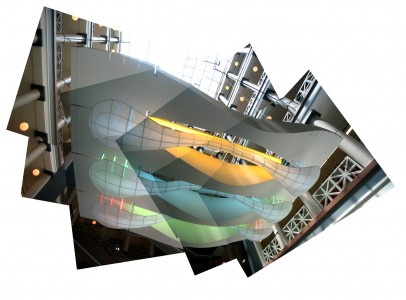

DigitalFabrication_8900_drinkTank-C-05

DigitalFabrication_8900_drinkTank-C-04

DigitalFabrication_8900_drinkTank-C-03

DigitalFabrication_8900_drinkTank-C-01

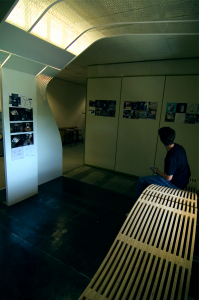

DigitalFabrication_8900_drinkTank-B

DRINKTANK This project created a unique and useful social space in the College. It seeks to answer a series of questions about how to provide free water, vessels for drinking, seating, lighting, and graphic signage within an integrated spatial system. The exploration that began on the ceiling datum like the LiteBEAM, but now folds down to become a wall with a double-curvature geometry. The form of the wall is determined by taking the width of the adjacent corridor at the base that transforms in section to the dimension of the existing modular ceiling grid and lighting system. The wall is self supporting while retaining a translucency to transmit natural and artificial light through fiber-optic effects demonstrated in the luminaire projects.