Learn More »

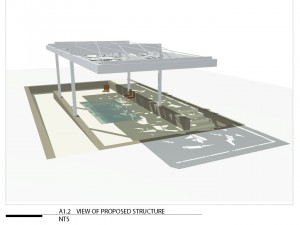

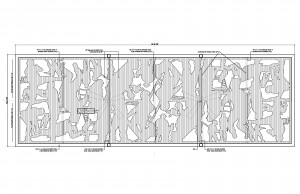

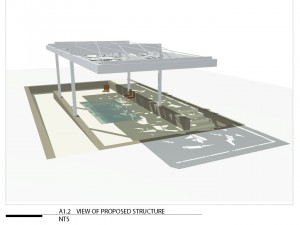

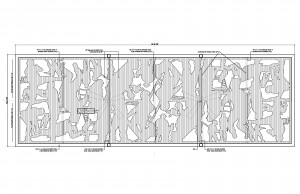

Designed by New York based installation artist Chris Doyle, is a Percent for Art project located at the City of Austin at the new Public Safety Training Facility. This permanent installation was designed as a modest, open-air shelter and includes a roof mural that was made through CNC cut perforations to the corrugated stainless steel canopy. The pavilion and canopy were fabricated and pre-assembled in Houston and shipped to Austin as a kit-of-parts that require minimal site work.

{work_brief}

« Close

October 08, 2013 by metalab

June 29, 2011 by Metalab Admin

June 29, 2011 by Metalab Admin

June 29, 2011 by Metalab Admin

June 29, 2011 by Metalab Admin

July 19, 2010 by Metalab Admin

June 21, 2010 by Metalab Admin

June 16, 2010 by Metalab Admin

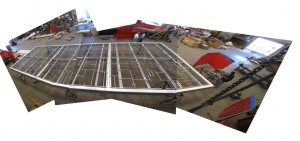

The Austin Training Pavilion canopy is complete and ready to ship as one integral assembly to the site. It will need an escort from Houston to Austin, look for it on I-10 next Friday. It will be installed on its four columns by four-point lift. Chris Doyle, Artist; Metalab, Digital Fabrication and CM.

May 05, 2010 by Metalab Admin

April 25, 2010 by Metalab Admin

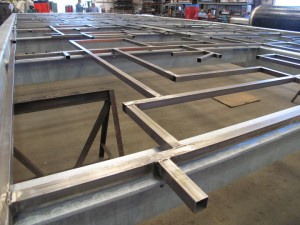

This pavilion will be built at the Austin Police Training Academy. Chris Doyle is the commissioned artist and METALAB is fabrication consultants and construction managers on the project. The canopy contains waterjet cut profiles held within a 16'x48' cantilevered frame. The frame is being galvanized in the largest hot dip facility in the region and will be shipped to the site as one complete assembly to be installed on the four columns. Campo Sheet Metal is fabricating and dry fitting the project here in Houston.

This pavilion will be built at the Austin Police Training Academy. Chris Doyle is the commissioned artist and METALAB is fabrication consultants and construction managers on the project. The canopy contains waterjet cut profiles held within a 16'x48' cantilevered frame. The frame is being galvanized in the largest hot dip facility in the region and will be shipped to the site as one complete assembly to be installed on the four columns. Campo Sheet Metal is fabricating and dry fitting the project here in Houston.